10” server racks are great for organising small equipment that is way too small for the full size of standard 19” racks.

DeskPi’s RackMate series is very nice. They’re available in 4U (model T0), 8U (T1) and 12U (T2). However, only the T1 is available in India, with the price inflated from USD 120 to INR 16,100, over 50%. I’ve obtained a T1 and like the quality, but don’t like the price and need a smaller rack, so I’ve made my own from aluminium extrusions. This is a guide to what I’ve learnt and how you can make your own.

Note

I use the terms “breadth” and “depth” here because FreeCAD uses “length” for the X axis and “width” for Y. This page originally used “width” to refer to the X axis and it manifested as CAD mistakes.

We’ll use 2020 extrusions. Either T-slot or V-slot will work. They have a square profile of 20mm, with a central mounting slot that is offset 10mm from either edge. But first, the relevant rack specs:

- Server racks use legacy imperial units instead of metric, reflecting their age (standards established 1910s–1930s).

- 10” and 19” originally referred to the outer breadth of the rack. The actual distance between the centres of the screw holes is a (somewhat arbitrary) 236.525mm (9.312”) for 10” and 465.12mm (18.312”) for 19”.

- Rail strips are 15.875mm broad. 2020 is larger at 20cm, so the distance between rails shrinks from 222.25mm (8.75”) to about 216mm. This should not matter in practice as the largest 10” mount I’ve encountered so far is 215mm. Equipment designed to maximise space usage in a 10” rack will be rare.

- One unit height (1U) is 1.75” or 44.45mm.

- There are three screw holes per side per U, positioned at 6.35mm from top/bottom and in the middle. Curiously, this means the middle hole is 15.875mm from the outer two, but each outer hole is only 12.70mm from the next unit’s outer hole. This vertical alignment is irrelevant when using 2020 extrusions because we have a continuous slot.

- Screws are typically 10-32”, which is similar to M5 with standard 0.8mm pitch, but not the same. M5 is very slightly larger and will have a tight fit in 10-32 threading, potentially stripping it. Some racks have square holes that accept a cage nut with your choice of thread. RackMate has 10-32” thread holes that also accept M5.

- There is no standard for the depth of the rack. RackMate T0 and T1 are 200mm deep, while T2 is 260mm. 200mm is just enough to fit a Mini-ITX board (170×170mm).

The first priority is to establish the spec breadth, so we’ll need one horizontal bar between two vertical bars (H shaped), sized to have 236.525mm between the mounting slots of the vertical bars. The slots are 10mm from the edge, so we deduct 20mm and round down, because it’s not possible to get sub-mm precision in consumer-grade metal cutting. An undersized cut can be padded at the joints and most rack mounts will have oversized holes to aid with centring. This gives us 216mm for the horizontal bar. To make a cuboid, we’ll need 4× 216mm.

Next, the height. 1U is 44.45mm, 4U is 4×, 177.8mm. We’ll round this up to 180mm because extra height is not a liability to the spec, while reduced height will make 1U unusable. To make a T or L join between extrusions, one of them has to be sufficiently longer. Add 20mm at either end. For 4U, that gives us 220mm per vertical bar, 4× total. Similarly, for 200mm depth we need 4× 160mm bars. These are our cutting specs, subject to some tweaking based on the joints:

- 4× 216mm (breadth)

- 4× 160mm (depth)

- 4× 220mm (height)

Next, the joints. A cube has eight corners, so we have eight three-way joints. There are three ways to make this joint, with differing costs (using prices from reliable vendors here):

- Use blind joints. 2020 has a central hole that’s the correct size to have an M5 thread tapped into it. To access this thread, the facing extrusion will need a hole cut into it 10mm from the end.

- ₹30 per tap ×16 = ₹480

- ₹70 per hole ×16 = ₹1120

- ₹3.40 per M5×16 BHCS screw ×16 = ₹54 (rounded down for bulk pricing)

- Total: ₹1654

- Use corner cubes. These are 20mm³ and have screw access holes on all sides. All three extrusions will need to be tapped but won’t need holes themselves. The vertical extrusions have to be shortened by 20mm at either end.

- ₹150 per corner cube ×8 = ₹1200

- ₹30 per tap ×8×3 = ₹720

- ₹3.40 per M5×16 BHCS screw ×8×3 = ₹80 (rounded down for bulk pricing)

- Total: ₹2000

- Use three-way connectors. These have arms that slide into the extrusion’s slots and can be screwed down. The extrusions don’t need taps or holes. These joiners don’t have the strength and precision of blind joints, but we don’t need that. A server rack is not a 3D printer with its sub-mm precision, moving mass, and metal-warping temperatures.

- ₹100-150 per joiner ×8 = ₹800–₹1200

Three-way connectors are the most cost effective. They add a 5mm cap to the vertical extrusions, so we reduce 10mm to get our new cutting dimensions for a 4U rack:

- 4× 216mm (breadth)

- 4× 160mm (depth)

- 4× 210mm (height)

- Total: 2344mm

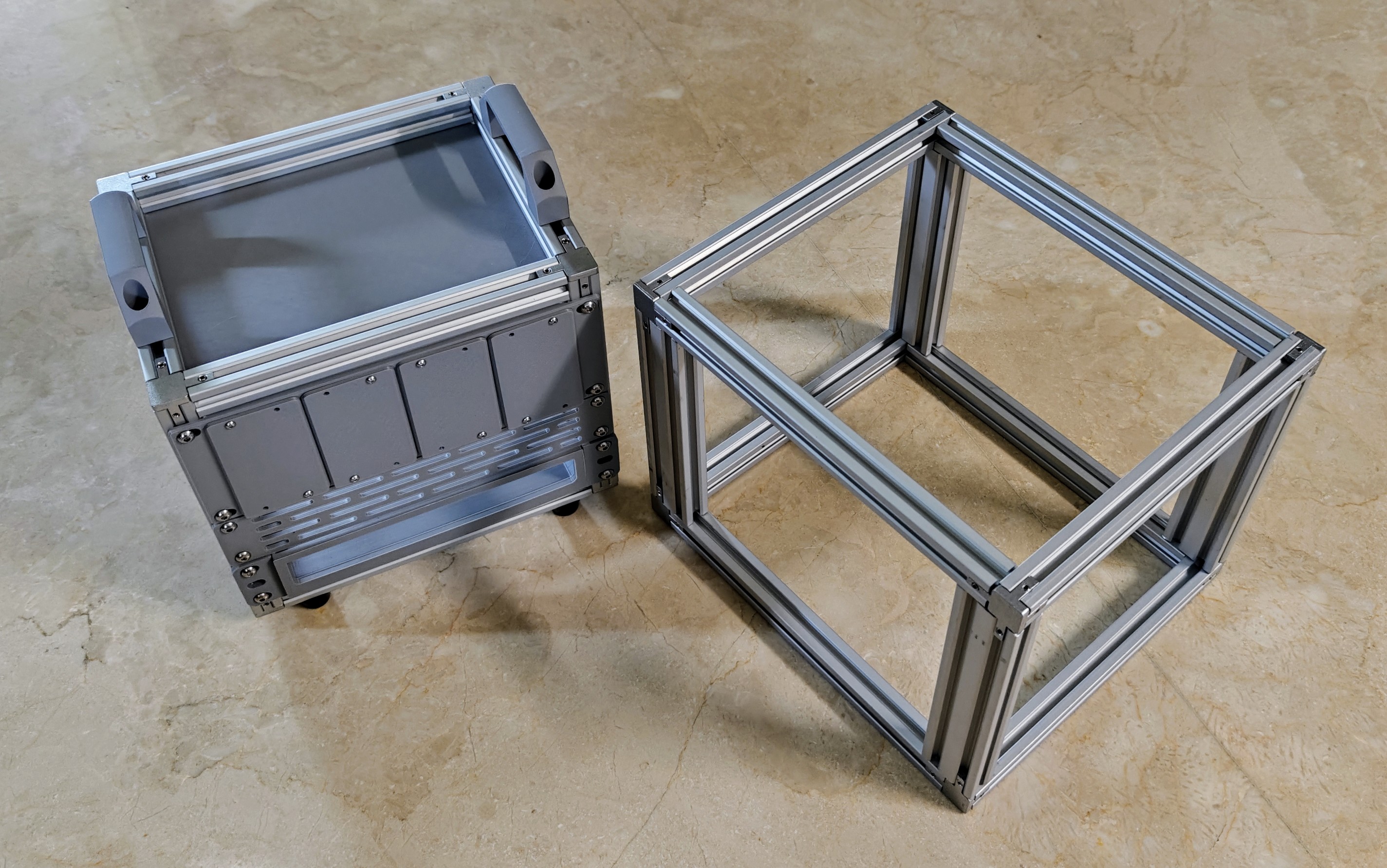

Extrusions are typically sold in 0.5 and 1.0 metre lengths. This will need 2.5m. Here’s a 4U built from these cuts using three-way connectors:

Mounting equipment

The mounting slots in 2020 extrusions can host a T-nut with M3, M4 or M5 threading. T-nuts have three varieties:

- Slide-in t-nut: These must be inserted from one end and slid to the required position. They have a fairly strong grip but are a pain to work with because you have to pre-insert them before closing the frame.

- Hammerhead t-nut: These are rectangular and can be dropped-in at any time. They rotate 90° to grip the slot when screwed down. They can fail to rotate sometimes and their grip strength is determined by whatever is on the other side. Plastic may not compress well enough for a good grip. Use these when you have a light load or are making a permanent installation.

- Spring-loaded t-nut: These cost more but have none of the disadvantages. They can be inserted at any time and hold their position in the slot using a spring-loaded ball bearing.

M5 is preferred for strength as rack mounts are cantilevered, unsupported on the rear. Screws are typically M5×8 as there is only 6mm depth in the slot. If your mounting plate is under 2mm (metal plate), add washers or switch to M5×6.

Power distribution unit

I have not found a PDU that has Type D sockets (Indian 6A) and fits 10” racks, so the options are to use a regular power strip, held down with cable ties or double-sided tape, or to build one using wall sockets and 3D printed casing. Fitting them within a 1U (44.45mm) height limit is tough as Indian sockets are typically taller:

- Anchor Roma: 55mm

- Legrand Arteor: 45mm

- MX: 42.4mm (fits!)

2U height clearance will allow for bulky adapters, and space usage can be optimised by mounting the PDU inward-facing on the rear side, or bottom mounted and facing up – better for loose-fitting chargers, like European Type C plugs inserted into Indian Type D sockets.

I made a power strip

The lack of a properly sized power strip was gnawing at me, so I learnt enough CAD to design my own. Model and instructions over on GitHub

Optimising cost with an arch frame

RackMate skips the bottom horizontal bars front/back to make an arch instead of a cuboid. This reduces weight and cost, but also reduces structural integrity as it depends on rack mounted equipment to reinforce the frame. This is fine for metal mounts but probably not for 3D printed plastic mounts. If we make the same choice and skip 2×216mm bars, the bottom three-way joiners can be replaced with cheaper two-way joiners. The total extrusion length for 4U is now 1932mm, within 2m. Or, for a taller 8U rack:

- 2× 216mm (breadth)

- 4× 160mm (depth)

- 4× 386mm (height)

- Total: 2616mm

This optimisation makes an 8U rack cost about the same as a fully reinforced 4U rack courtesy cheaper 2-way connectors. Extrusions themselves are available at a range of prices varying by quality, surface finish, and supplier logistics. Once again, we’re not building a high stress frame, so the cheapest material is good enough, as long as it’s in your preferred surface finish. We’ll typically have two choices: raw aluminium (labelled “silver”) or anodised black.

If choosing black, note that the cut surfaces are not anodised. Connectors are only available in raw finish, so colouring them black becomes an extra DIY project. Screws are available in both stainless steel and alloy steel with black oxide coating, but the backing nuts are typically only stainless.

Optimising space with 2040 extrusions

My reference use case is a portable kit for recording audio and video at meetups. This requires a computer, capture cards, one or more cameras, and microphones that may also be connected to the venue’s sound system.

These components need to be wired up correctly and a rack is great for ensuring the wiring is correct before it’s shipped to a venue. This departs from the typical use of a server rack, which is meant to afford adding or removing equipment without disturbing other equipment, therefore placing all of the wiring on the outside. We want most of our wiring inside, only exposing the necessary external interfaces (typically HDMI, audio, ethernet).

Our audio interface may be:

- Primary: We do audio mixing on the rack and send final output to the venue’s sound system, or

- Secondary: Venue gives us the final output and we just record, or

- Independent: Entirely separate from the venue’s audio.

If we’re doing primary, we need an audio mixer, which has a large surface for its user interface and can’t be inside the rack. It’ll be on top. We want to avoid having it separate because that’ll mean extra setup and a greater risk of incorrect wiring.

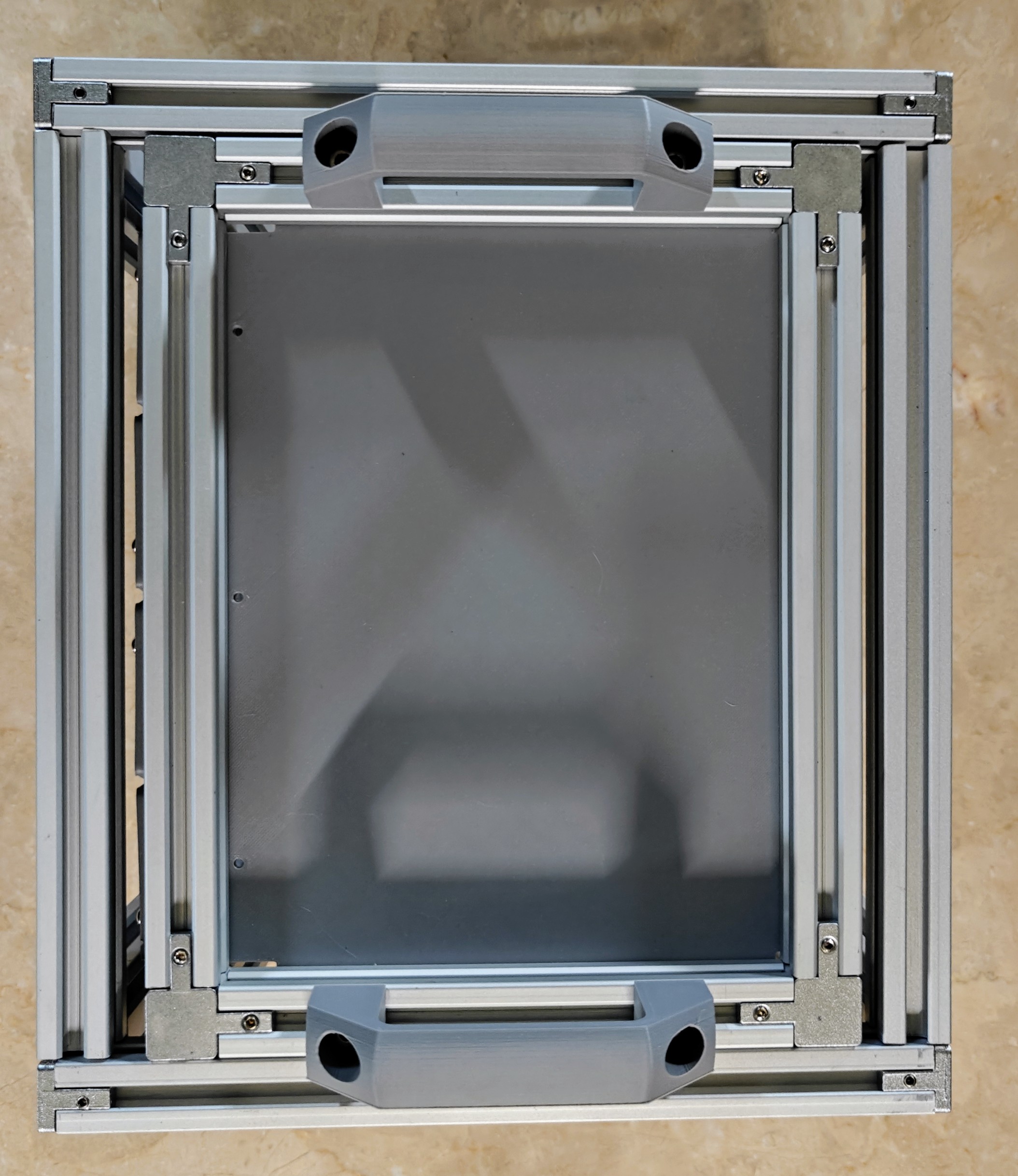

My candidate mixer is a Behringer Flow 8, which offers each of its 8 analog inputs as a digital audio stream, allowing each to be processed separately. The Flow 8’s dimensions are 229B×172D×48H mm, slightly more than the cavity of the frame from the dimensions calculated above: 216B×160D×20H mm.

To make a larger rack that can accommodate this mixer while also sticking to the 10” spec, we can use 2040 extrusions for the vertical posts. This adds 40mm to the breadth. The top plate and its mounting screws overlap with the top 1U’s space, so we’ll need an additional 5–10mm height margin:

For the extra depth: if we make it 256mm, all six faces of the rack will now be 10” compliant, allowing equipment to be mounted from any direction. Three-way connectors are designed for 2020 as the central column, so the 2040 can’t be used there. We’ll need to reorient (or switch to two-way connectors). New cutting dimensions:

- 2020 for breadth: 256mm ×4

- 2020 for depth: 246mm ×4 (10mm less for the 3-way connectors)

- 2040 for height: 4U+10mm margin = 188mm ×4

4×256mm exceeds 1m, so there’s another choice to make:

- Cut the fourth 256mm from another piece of extrusion. Some suppliers sell 500mm and 300mm lengths.

- Skip it. The frame should be strong enough with one piece missing.

- Connect the two leftover 2020 pieces with inline connectors and and then cut to 256mm. (This sort of cut may be too complicated to explain to a supplier; expect to DIY.)

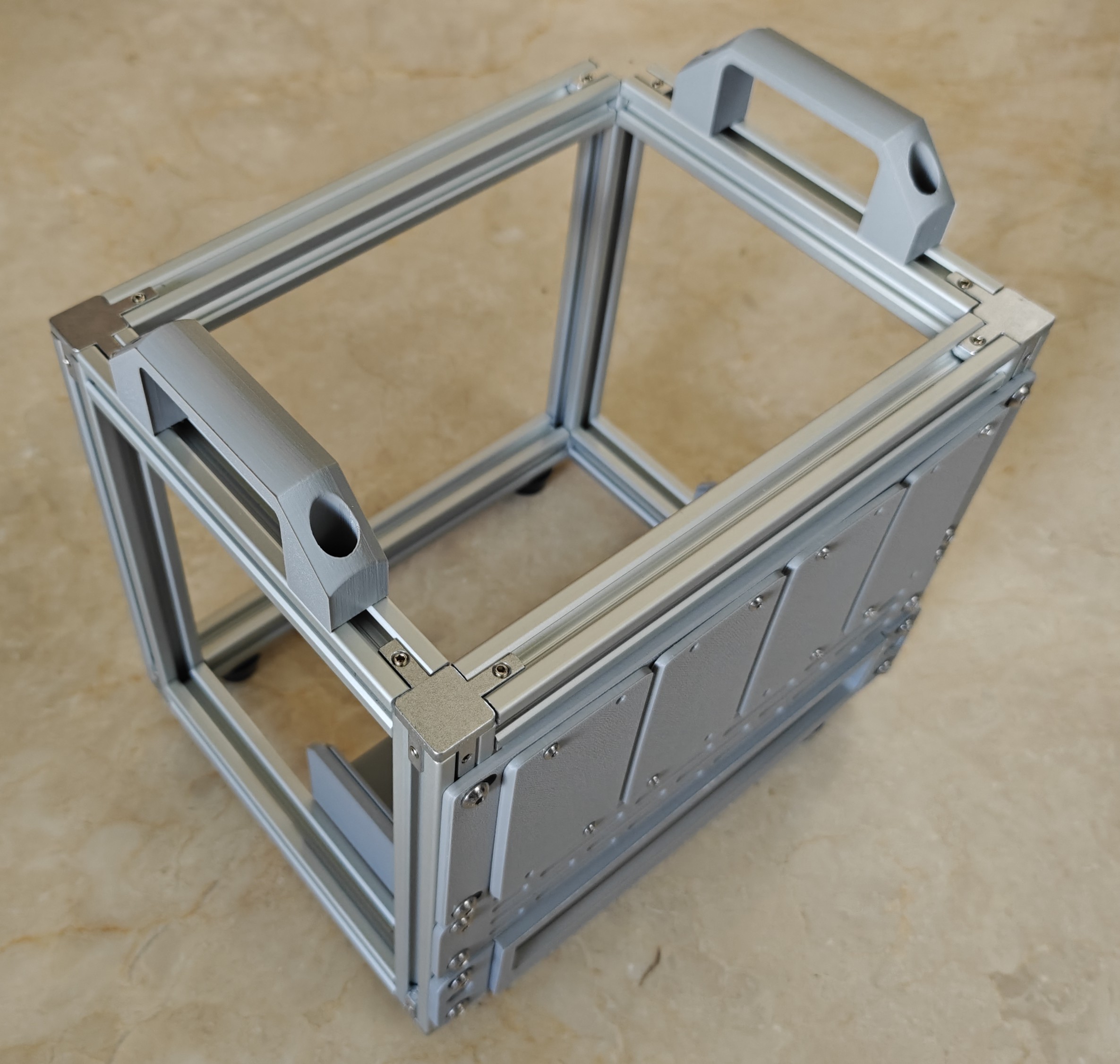

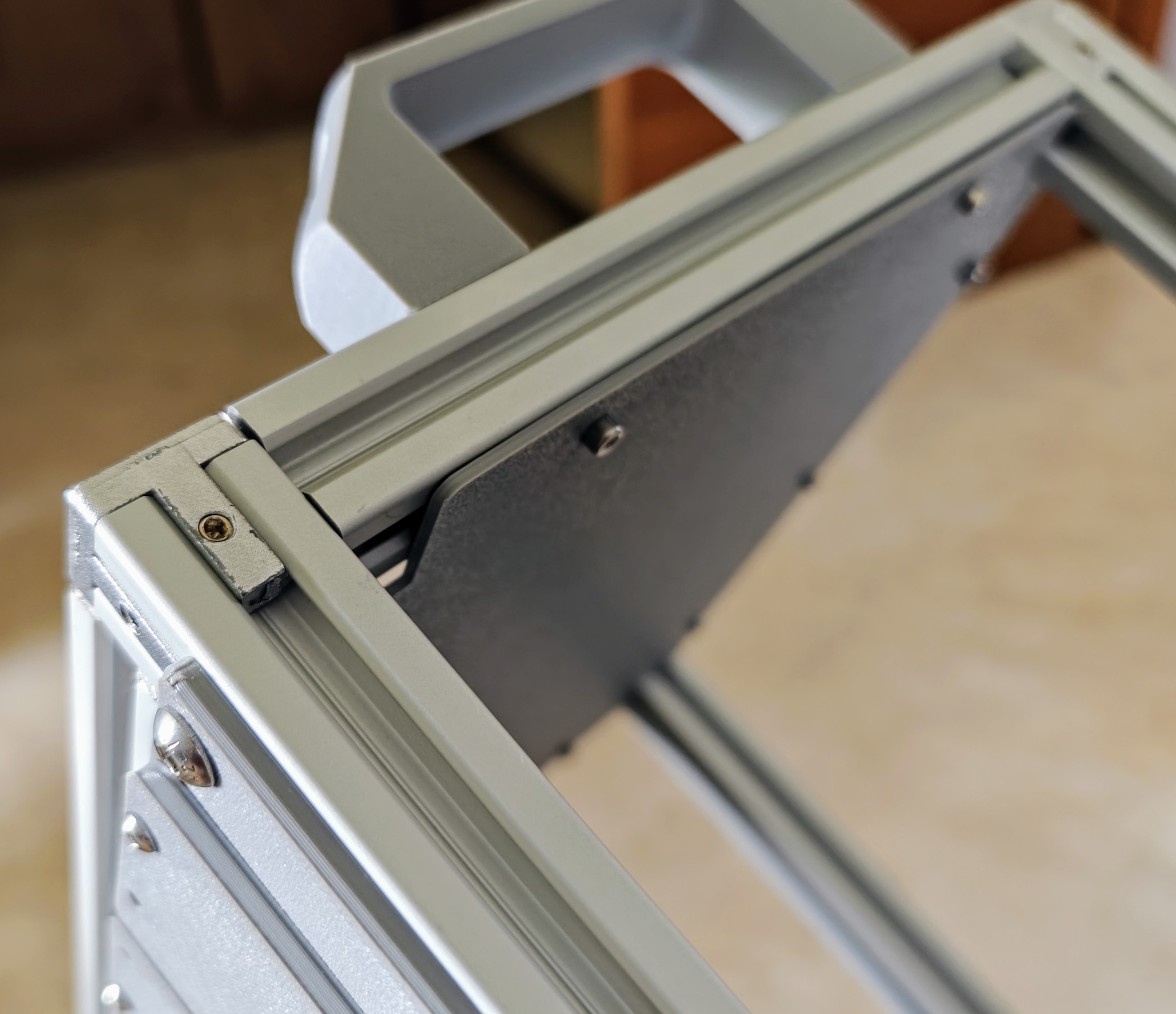

Here’s a build. I cut the extrusions at home this time using an angle grinder mounted on a stand. It has no angle markers and the cuts came out slanted, but it still works because three-way connectors are forgiving. They clamp into the slots, not the cut faces.

Note the 3-way connectors are now reoriented to be front-facing.

After building this I’ve realised I could have just used 2020 with greater depth and turned the rack sideways. Side-mounted equipment and cabling is better for this use case.

Expansion for 19” equipment

This week I found myself setting up a Unifi gateway and 8-port switch in a 4U 19” rack that is way too large for them – but the switch at about 24cm is also too large to fit a 10” rack. u/DatBdz over on Reddit solved for this by mounting 19” equipment vertically. We can do that too – our vertical extrusions need 465mm clearance, a little over 10U height. Applying this to the variants described above:

| Model | Breadth | Depth | Height |

|---|---|---|---|

| 10”+19” 200mm | 4× 2020 216mm | 4× 2020 160mm ±flexible | 4× 2020 495mm |

| 10”+19” 200mm arch | 2× 2020 216mm | 4× 2020 160mm ±flexible | 4× 2020 500mm |

| 10”+19” multisided | 4× 2020 256mm | 4× 2020 246mm | 4× 2040 465mm |

Make it a cube

Our 10” rack is 256mm wide since we rounded down for the lack of cutting precision. It should be 256.525mm if cut precisely, but that’s not attainable and also not necessary. I don’t know about you, but this number – 256, 2⁸ – is rather satisfying to me, so what if we make the rack 256mm in every dimension? 256mm³, a proper cube. This makes it a little under 5U in every orientation on every face, allowing us to to pack equipment into the cube like a tetris puzzle. Cutting dimensions, for joints using 3-way corner connectors:

- 4× 246mm

- 8× 216mm

- Total: 2712mm

Here’s my work-in-progress video kit built on a cube:

Sourcing

I’ve only listed vendors I’ve personally purchased from. Recommended sources are highlighted.

You may find better rates in your city’s local hardware market, so please do explore. Chances are they only sell in bulk, and may be overall difficult to find and order from as a one-time buyer. If there’s enough interest in building these racks, I’ll attempt setting up supply.

2020 and 2040 extrusions (price per metre)

Cutting extrusions yourself is not recommended unless you have have the necessary tools and know how to use them.

- 3DPrintronics:

- With optional cutting (free), tapping (₹30 each) and holes (₹70 each)

- ==2020 V-slot silver ₹469==

- 2020 V-slot black ₹589

- 2040 V-slot silver ₹889

- 2040 V-slot black ₹998

- Fastdep:

- 2020 T-slot silver ₹379

- 2020 V-slot silver ₹379

- 2040 T-slot silver ₹798

- 2040 V-slot silver ₹798

- Misumi:

- Available in sizes up to 4m, with additional customizations. Misumi calls their 2020 T-slot “5 series with 6mm slot”

- ==2020 T-slot silver (LCF6-2020-?) ₹270==

- ==2040 T-slot silver (LCF6-2040-?) ₹470==

- Novo3D:

- 2020 V-slot black out of stock

- 2040 V-slot black out of stock

- Robotics DNA:

- 2020 T-slot silver ₹483.80

- 2040 T-slot silver ₹767

- Robu:

- 2020 T-slot silver ₹413

- 2020 V-slot black ₹440

- 2040 T-slot silver ₹839

- 2040 V-slot black ₹1049

Connectors (price for each, lower in bulk)

- DConqueror3D:

- Misumi:

- Novo3D:

- 2-way blind connector ₹45

- ==3-way blind connector ₹89==

- Robotics DNA:

- Cube corner 2-way silver ₹95.01

- Cube corner 3-way silver ₹95.01

- ==2-way blind connector ₹35==

- 3-way blind connector ₹148.99

- Robu:

M5 screws and nuts (price for each, lower in bulk)

Acronyms:

- BHCS: Button Head Cap Screw (their cap size profile is necessary for cube corners and blind joints, and it has more surface area than socket-head screws for gripping rack mount plates)

- SHCS: Socket Head Cap Screw, more common for high strength uses, but with a larger protrusion than button-head screws

- FHCS: Flat Head Cap Screw, countersunk to not protrude, but need chamfered (angled) screw holes

- SS: Stainless Steel, followed by a grade number. The austenitic family (200 and 300 series) is non-magnetic

- Black screws are carbon steel with black oxide coating. 10.9 is an ASTM F568M grade. These will rust if the coating is stripped and the metal is exposed to moisture or humidity

M5×16 is for cube corners and blind joints. M5×8 should be sufficient for all rack mounts, but thinner mounting plates will need M5×6 or padding washers.

- 3DPrintronics:

- M5×8 BHCS SS ₹6.50

- M5×8 BHCS black ₹10.40

- M5×16 BHCS SS ₹8.00

- M5×16 BHCS black ₹7.10

- DConqueror3D:

- M5 slide-in t-nut ₹9.00

- ==M5 hammerhead t-nut ₹8.00==

- ==M5 spring-loaded t-nut ₹15.00==

- Fastdep:

- M5×16 BHCS black ₹3.80

- Novo3D:

- M5 slide-in t-nut ₹10.50

- ==M5 hammerhead t-nut ₹4.00==

- ==M5 spring-loaded t-nut ₹15.00==

- OnlyScrews:

- Price does not include tax

- ==M5×8 BHCS SS 304 ₹3.20==

- ==M5×8 BHCS 10.9 black ₹2.80==

- M5×16 BHCS SS 304 ₹3.40

- M5×16 BHCS 10.9 black ₹2.50

- Robotics DNA:

- M5×16 BHCS black ₹5.60

- M5×8 BHCS black ₹7.08

Acrylic sheets

Prices vary by colour and dimensions. 3mm sheet should be sufficient for side panels.

Power sockets

- Amazon:

- MX-620 3× socket power strip ₹1599. This is a bit taller than 1U and will not fit a 2020 extrusion rack from the outside. However, it can be mounted on the backside of the extrusions

- ==IEC C14 socket with switch and fuse ×2 ₹149==

- Type D to C13 cords: search for “computer power cable”

- MX MDR Electronics:

- MX-620 3× socket power strip ₹1800 (cheaper on Amazon)

- MX-4139 8× USB-A 5V 2.1A power strip ₹2100 (not tested for fit)

- ==MX-3121 multistandard mains power socket ₹68==

- MX-3122 Type C&D mains power socket ₹62

- MX-3122A 2× Type C&D mains power socket ₹120

- MX-2835 IEC C14 socket and fuse with mounting holes ₹98

- MX-3194 IEC C14 socket and fuse ₹68

- MX-3195 IEC C14 socket and switch ₹98

- Type D to C13 cords (category page)

- Robotics DNA:

- ==1U 2× USB-A ₹325== (same size and finish as the MX-3121 sockets, but of unknown make)

- 1U USB-A+USB-C ₹325 (appears to be made by Yueqing Shengtuo Electronics Co., Ltd. under the brand name “Seto”)